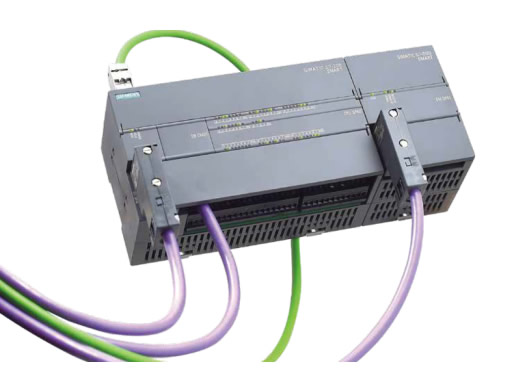

The polypropylene spinning machine adopts a new type of spinning box machine and a uniformly mixed melt pipeline, a large-plate spinneret, a circular or rectangular top with self-sealing components, a metered planetary gear pump and a lifting and quick-release drive rod , Uniform and stable side blowing device, large flow spray oiling system, environmentally friendly and energy-saving medium electric heating system, imported intelligent instrument control, additional continuous switching filter can use renewable raw materials to produce Puqiang filament, hot roller adopts foreign advanced technology , The surface temperature difference is small, the inner temperature of the coil is low, and the hot roller specifications are complete to meet various needs. The polypropylene spinning machine has the characteristics of high speed, energy saving, good tow puffing and deformation, energy-saving spinning box, low energy consumption, bottom-mounted components, the hot roller uses electric induction heating, and adopts heat pipe method or multi-stage temperature control technology. The temperature of the working area on the surface of the hot roller is uniform and reliable, and the automatic winding head has a high switching success rate and good forming. In order to increase the output of the machine, high-speed spinning, the spinning speed is 3500-4000 m/min, even as high as 5000 m/min, large packages, the package volume of each package can generally reach 10 kg to tens of kg, continuous Formation, spinning and drawing are completed on a spinning machine at the same time. Some spinning, drawing, and texturing processes are all completed on a spinning machine, which has been applied in polypropylene production.

You are here:Home > Company News

Explore the structural principle of polypropylene spinning machine

Release date:2020-06-19 Popularity:2499

| Previous:No previous record |

| Next:Analysis of the development trend of the textile industry in 2020! |

Related articles

- What are the main components of the sp..2022-08-08

- Introduction to the main characteristi..2022-01-07

- Function of taisida polypropylene fibe..2021-12-03

- What is the function of tesda polyprop..2021-06-25

- Taisida polypropylene spinning machine..2021-05-06

- Characteristics of polyester POY spinn..2021-01-04

- Basic parameters of polyester BCF spin..2020-12-24

- Working principle of polypropylene spi..2020-12-21