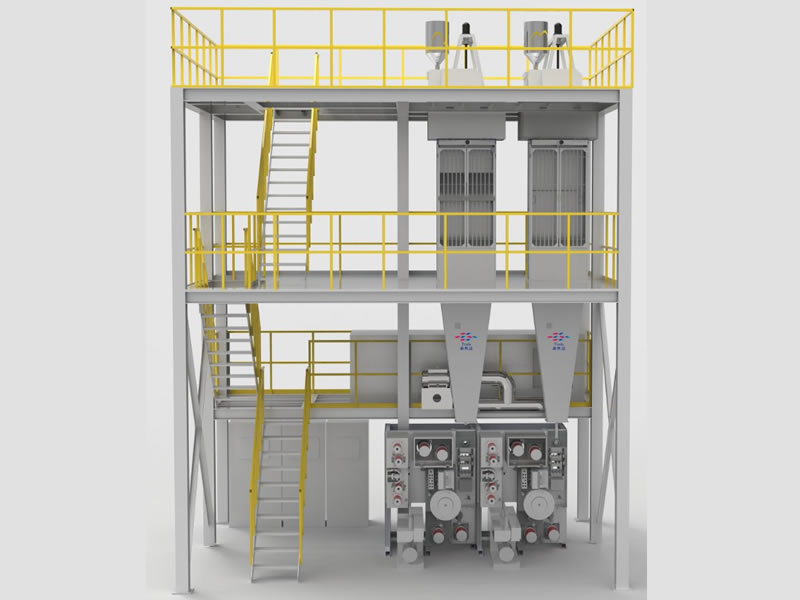

PP/PA (T300)-BCF spinning machine

Source:Suzhou Tesda Intelligent Technology Co., Ltd.

main feature:

1. This machine uses PA/PP as raw materials to produce BCF yarns with a single process of spinning, drawing and texturing;

2. With a gravity batching system to ensure the accurate addition ratio of color masterbatch and main raw materials;

3. Special extruder design, suitable for a variety of polymer production;

4. The special spinning box has uniform distribution of solution and no dead corners. The round or rectangular spinning components are used for easy replacement and prolonged cycle;

5. Adopting a new type of side blowing cooling device, no wind pressure fluctuation, the cooling air conditioner can be adjusted to the required temperature, relative humidity, wind speed and wind pressure distribution;

6. Specially designed monomer suction system, which can discharge oligomers and lactams;

7. The cooperation between the new nozzle-type deforming device and the optimized cooling drum ensures excellent puffing and curling.

8. The heating roller adopts high frequency heating by reading electric induction, and the surface temperature of the roller body is uniform and adjustable;

9. It adopts fully automatic switching winder, the yarn tension is constant, the switching success rate is high, and the shape is beautiful.

specification

|

project |

data |

|

Final size/hole number |

700-3500d/68-140f |

|

Winding speed |

1800-3200 m/min |

|

Spinning method |

Screw melt spinning |

|

Number of heads per person |

2、3、4 |

|

Spinneret |

Ø95、Ø100、Ø170 mm Rectangle 240*170mm |

|

Component |

Bottom cup type |

|

Quenching method |

Side blowing |

|

Hot roll |

Ø190*330mm |

|

Deformer |

Friction blade |

|

Cooling drum |

Ø400mm Air-cooled |

|

Winder |

Automatic winding head | |

|

| 【Print this page】 【Return】 |