Product Usage

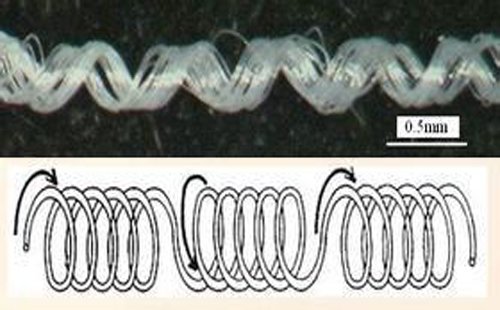

The spinning machine is suitable for the production of composite ultra-fine fibers with high added value, such as polyester and nylon composites, polypropylene modified bicomponents, such as POY and FDY. Type ultra-fine or irregular, round single component.

main feature

1. Two sets of extruder are used to squeeze and melt the two components;

2. Two sets of melt pipelines with static mixer and continuous switching filter;

3. The temperature of spinning box is controlled separately, with refrigeration valve, two sets of vertical metering pump drive system and two sets of high precision planetary gear pumps;

4. Rectangular, cup-shaped composite components are loaded on top or bottom, with various types of two-component spinnerets;

5. The wind speed of the side blowing system is uniform and stable;

6. Two sets of biphenyl systems with safety devices, uniform and reliable heating;

7. Equipped with a precise pressure and temperature controller, which can realize the functions of setting, control, detection and recording;

8. High-speed automatic switching winding head is adopted, with high success rate and good cake formation.

specification The spinning machine is suitable for the production of composite ultra-fine fibers with high added value, such as polyester and nylon composites, polypropylene modified bicomponents, such as POY and FDY. Type ultra-fine or irregular, round single component.

main feature

1. Two sets of extruder are used to squeeze and melt the two components;

2. Two sets of melt pipelines with static mixer and continuous switching filter;

3. The temperature of spinning box is controlled separately, with refrigeration valve, two sets of vertical metering pump drive system and two sets of high precision planetary gear pumps;

4. Rectangular, cup-shaped composite components are loaded on top or bottom, with various types of two-component spinnerets;

5. The wind speed of the side blowing system is uniform and stable;

6. Two sets of biphenyl systems with safety devices, uniform and reliable heating;

7. Equipped with a precise pressure and temperature controller, which can realize the functions of setting, control, detection and recording;

8. High-speed automatic switching winding head is adopted, with high success rate and good cake formation.

specification

|

||||||||||||||||||||||||||

| 【Print this page】 【Return】 |