Product Usage:

This machine adopts spinning, drafting and winding one-step production process technology. Firstly, high-quality polyester / nylon mother yarn (for splitting) is made, and then the single yarn is obtained through the splitting machine or the split warping mechanism.

main feature:

1. Compared with the traditional two-step process, this type has the characteristics of short process flow, small footprint, less labor, high output, low production cost, and good product quality.

2. The combination of special spinneret and quenching device effectively improves the cooling and forming of the mother yarn.

3. Specially designed oiling and drafting devices have improved the spinnability of the mother yarn.

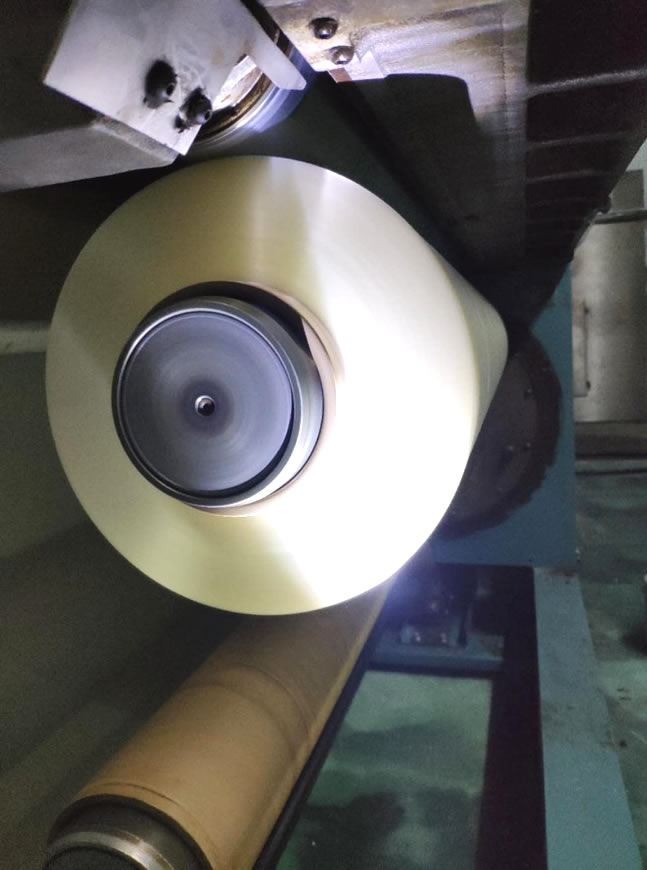

4. The hot drafting roller adopts induction heating, and the surface temperature of the working area of the hot roller is uniform and reliable through the heat pipe uniform temperature method.

5. Adopting high-speed full-automatic tube changing winding head, high switching success rate and good forming.

Specification

Note: Not all parameters can be arbitrarily combined, and the equipment configuration depends on the requirements of the variety specifications. |

||||||||||||||||||||||||

| 【Print this page】 【Return】 |